The Genesis of 3D Printing

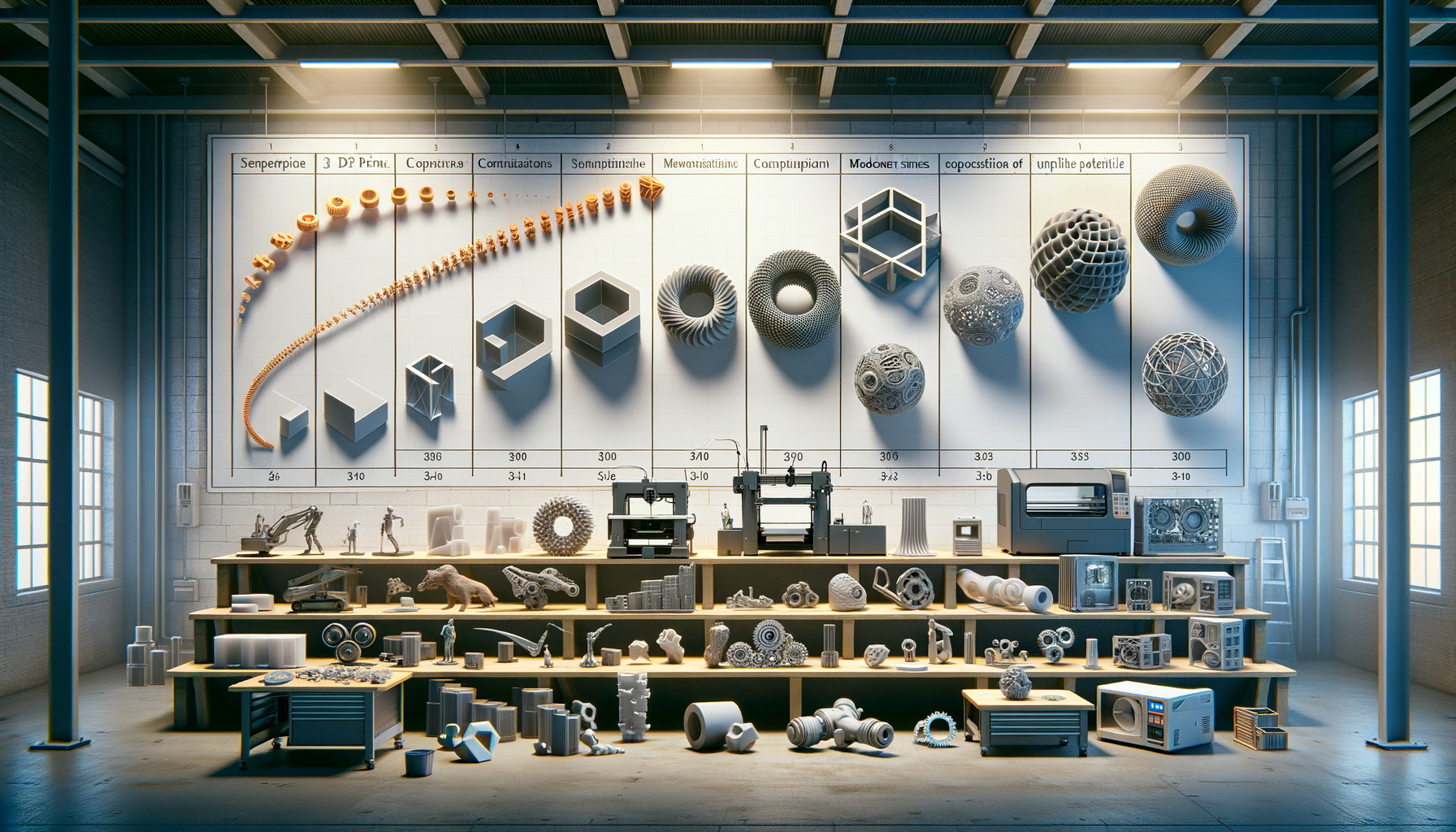

The roots of 3D printing, also known as additive manufacturing, can be traced back to the 1980s, a decade characterized by rapid technological advancements. The initial concept revolved around creating three-dimensional objects by layering material based on digital models. This was a revolutionary idea at the time, setting the stage for what would become a transformative technology in various industries.

The first patent for 3D printing technology was filed by Dr. Hideo Kodama of the Nagoya Municipal Industrial Research Institute in 1981. However, it wasn’t until 1984 that Charles Hull invented stereolithography, a process that allowed designers to create 3D models using digital data. Hull’s invention was a pivotal moment, leading to the development of the first 3D printer by 3D Systems Corporation.

Throughout the 1990s, 3D printing technology continued to evolve, with innovations such as selective laser sintering (SLS) and fused deposition modeling (FDM) emerging. These advancements broadened the scope of materials that could be used, including plastics, metals, and ceramics. As technology progressed, the cost of 3D printing decreased, making it accessible to a wider audience and paving the way for its integration into mainstream manufacturing processes.

Revolutionizing Industries

The impact of 3D printing on various industries is profound, reshaping traditional manufacturing processes and enabling new possibilities. In the healthcare sector, for example, 3D printing has revolutionized the production of prosthetics and implants, allowing for customized solutions tailored to individual patients. This has significantly improved patient outcomes and reduced costs.

In the automotive and aerospace industries, 3D printing has enabled the creation of complex parts that are lighter and more efficient than those produced through traditional methods. This not only enhances performance but also contributes to sustainability by reducing material waste. Moreover, the ability to rapidly prototype and test parts has accelerated innovation and reduced time-to-market.

The fashion industry has also embraced 3D printing, with designers using the technology to create unique, intricate designs that were previously impossible to achieve. This has led to a surge in creativity and innovation, allowing designers to experiment with new materials and forms.

- Healthcare: Customized prosthetics and implants

- Automotive: Lightweight, efficient parts

- Fashion: Unique, intricate designs

Challenges and Limitations

Despite its many advantages, 3D printing technology faces several challenges and limitations. One of the primary concerns is the speed of production. While 3D printing is excellent for prototyping and small-scale production, it is often slower than traditional manufacturing methods when it comes to mass production. This can be a significant drawback for industries that require high-volume output.

Another challenge is the range of materials available for 3D printing. Although the technology has advanced significantly, the variety of materials that can be used is still limited compared to traditional manufacturing. This can restrict the types of products that can be created using 3D printing.

Additionally, there are concerns about the quality and consistency of 3D-printed products. While advancements have been made in improving the precision and accuracy of 3D printers, ensuring consistent quality across large batches remains a challenge. This is particularly important in industries such as aerospace and healthcare, where product reliability is critical.

- Speed of production

- Limited material range

- Quality and consistency concerns

Future Prospects and Innovations

The future of 3D printing technology is bright, with numerous innovations on the horizon that promise to further enhance its capabilities. One of the most exciting developments is the advent of bioprinting, which involves using 3D printing technology to create living tissues and organs. This has the potential to revolutionize the field of medicine, offering new solutions for organ transplants and regenerative medicine.

Another promising area of development is the use of 3D printing in construction. Researchers and companies are exploring the possibility of using the technology to build entire structures, such as houses and bridges, which could significantly reduce construction time and costs. This could have a profound impact on addressing housing shortages and infrastructure development.

Furthermore, advancements in material science are expanding the range of materials that can be used in 3D printing, including biodegradable and sustainable options. This aligns with the growing emphasis on sustainability and environmental responsibility, making 3D printing an increasingly attractive option for eco-conscious industries.

- Bioprinting: Living tissues and organs

- Construction: Building structures

- Material advancements: Biodegradable and sustainable options

Conclusion: Embracing the 3D Printing Revolution

3D printing technology has come a long way since its inception, evolving from a novel concept to a powerful tool with the potential to transform industries and improve lives. Its ability to create complex, customized products with minimal waste offers significant advantages over traditional manufacturing methods. However, challenges such as production speed and material limitations must be addressed to fully realize its potential.

As we look to the future, the continued development of 3D printing technology promises to unlock new possibilities and drive innovation across various sectors. By embracing this revolution, industries can not only enhance their capabilities but also contribute to a more sustainable and efficient future. The journey of 3D printing is far from over, and its impact will undoubtedly continue to unfold in exciting and unexpected ways.

Leave a Reply